HARRISBURG FACILITY INCINERATOR

SEPTEMBER, 2004

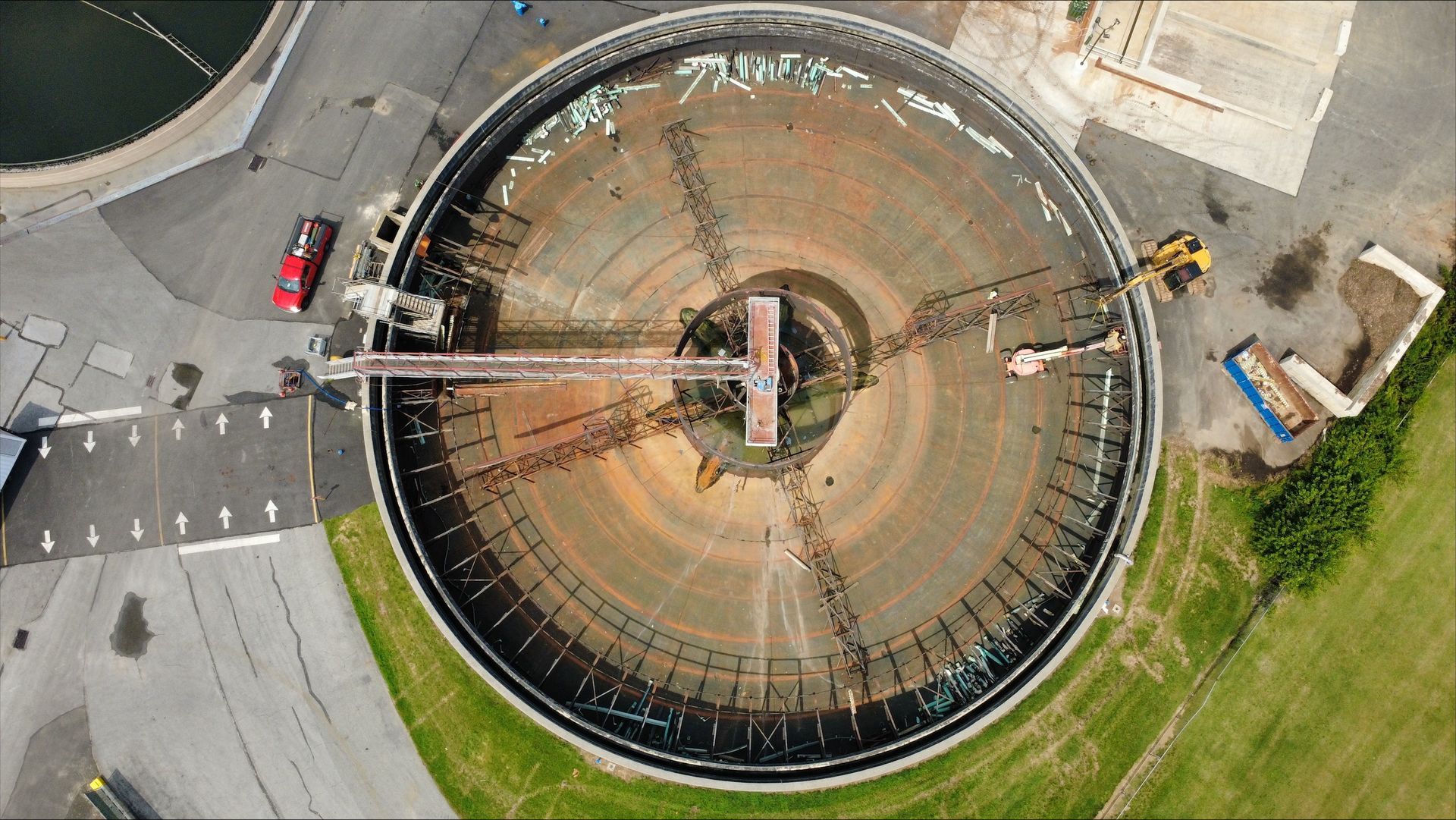

The Harrisburg Authority decided it was time to replace their incinerator structure. NADC member Empire Services once again was out to prove that they are the company to call and had the team to perform the necessary work for the excavator demolition project. Prove it they did! The Harrisburg Materials, Energy, Recycling, and Recovery Facility has been engaged in the business of combusting municipal solid waste for over thirty years. The facility was originally constructed and placed into commercial operation in 1972. The original plant consisted of two mass -burn combustion units, each designed to combust 360 tons per day.

Empire Services had 44 days to complete the project. It consisted of the removal of two large precipitator units, dismantlement of two 90’ incinerators, removal of two overhead cranes from inside the building, demolition of the cooling tower, ash building, sludge bins, turbines and mechanicals throughout the incinerator, and turbine buildings. With this time frame, it was necessary for Empire Services to create scheduling that allowed the crew to handle this difficult project in the most efficient and safe manner possible. Empire determined the work schedule would require two ten-hour shifts with twenty men on each shift. They also decided that the roof and steel beams would be left in place to avoid any possible loss of time due to weather problems. This decision assisted in providing temporary lighting and a location for the workers to tie off when doing high work. With this workforce, Empire met the required deadline to complete the demolition project. This was due in no small part to the crew assigned to this job and their dedication to getting the job done.

Prior to the start of the work, Empire was required to develop a dust control plan to deal with the enormous amount of ash build-up throughout the building which had to be approved by DEP. This was accomplished through Empire’s sister company, Elk Environmental, which washed down the entire facility, filtering all the water to prevent sludge and ash from entering the sanitary sewer system. Air monitoring was used in the facility and employees themselves were checked with hand held monitoring devices. A genuine concern of Empire is to provide a safe working environment for their employees. Any and all safety issues were addressed with the presence of Empire’s Safety Officer onsite. There were weekly Safety Meetings held and continuous onsite safety inspections.

One of the many hurdles Empire had to overcome was that the main building had to remain intact in preparation for the new incinerator. The first step was to remove the precipitators which were 40 feet above the roof of the one building and 30 feet below into the basement. The precipitators were removed using our 95’ long boom Hitachi 450equipped with a LaBounty MS15 shear. The use of specialized equipment and trained employees allowed Empire to perform within the confines of the job site.

The next step was to insert a twenty-foot wide corridor within the concrete walls to allow access into the building. With the precipitators removed, Empire installed a ramp to gain access into the basement at which time all the conveyors and mechanicals were removed. This allowed the workers room to attack the main incinerators. The north wall was removed and the dismantlement could begin.

The top ten feet of the incinerator pressure vessels had to be burned out by hand so that the long reach could be used for the removal of the remaining portion of the structure. The main dismantlement of the incinerators required the Hitachi 450 with 95’ long boom and the Hitachi 300 with 70’ long boom and LaBounty UP20 shear and grapples. The entire height of the incinerators reached 95’.

During this time, several crews worked throughout the two buildings removing mechanicals, numerous tanks, the turbine, and the entire concrete and steel second floor in the turbine building.

Upon completing the incinerator the 8” thick concrete roof and steel needed to be removed. Due to tight working conditions, Empire decided to mobilize our Brokk machine equipped with a hammer. This made quick work of the process. This machine was also used to remove the roof area over the loading bins where Empire needed to remove and reinstall the concrete, steel, and decking to gain access to the overhead cranes. The overhead cranes weighing 45,000 pounds each were removed using a 150-ton Omega crane. The Brokk machine was also used in removing the entire second floor deck in the turbine building.

As the project ended, Empire had removed in excess of 2000 tons of scrap, and 1200 tons of ash.

From beginning to end of this demolition project, Empire was responsible for all aspects of this job including safety barriers, OSHA railings, lay-down area fencing, and all utility disconnects.

The entire Empire team was commended by the GC on this particular demolition project for their coordination of the all stages and working well together on a very difficult endeavor.

If it is a demolition project of any size requiring expertise and skill, Empire Services is the company to contact.