Repurposing a Historical Manufacturing Site: Allentown Metal Works

There was a time in the Lehigh Valley when all the cities were thriving with great industry like Bethlehem Steel, Western Electric and Mack Trucks, but those days are now long gone. At times it can be disheartening to demolish one of these venerable structures. Yet, knowing that by removing the unusable and unsafe portions of a property so that the remaining integral portions can be repurposed into new life makes the work very rewarding. This is especially true when the work brings back manufacturing and jobs to an area where it has been hard to come by in recent years.

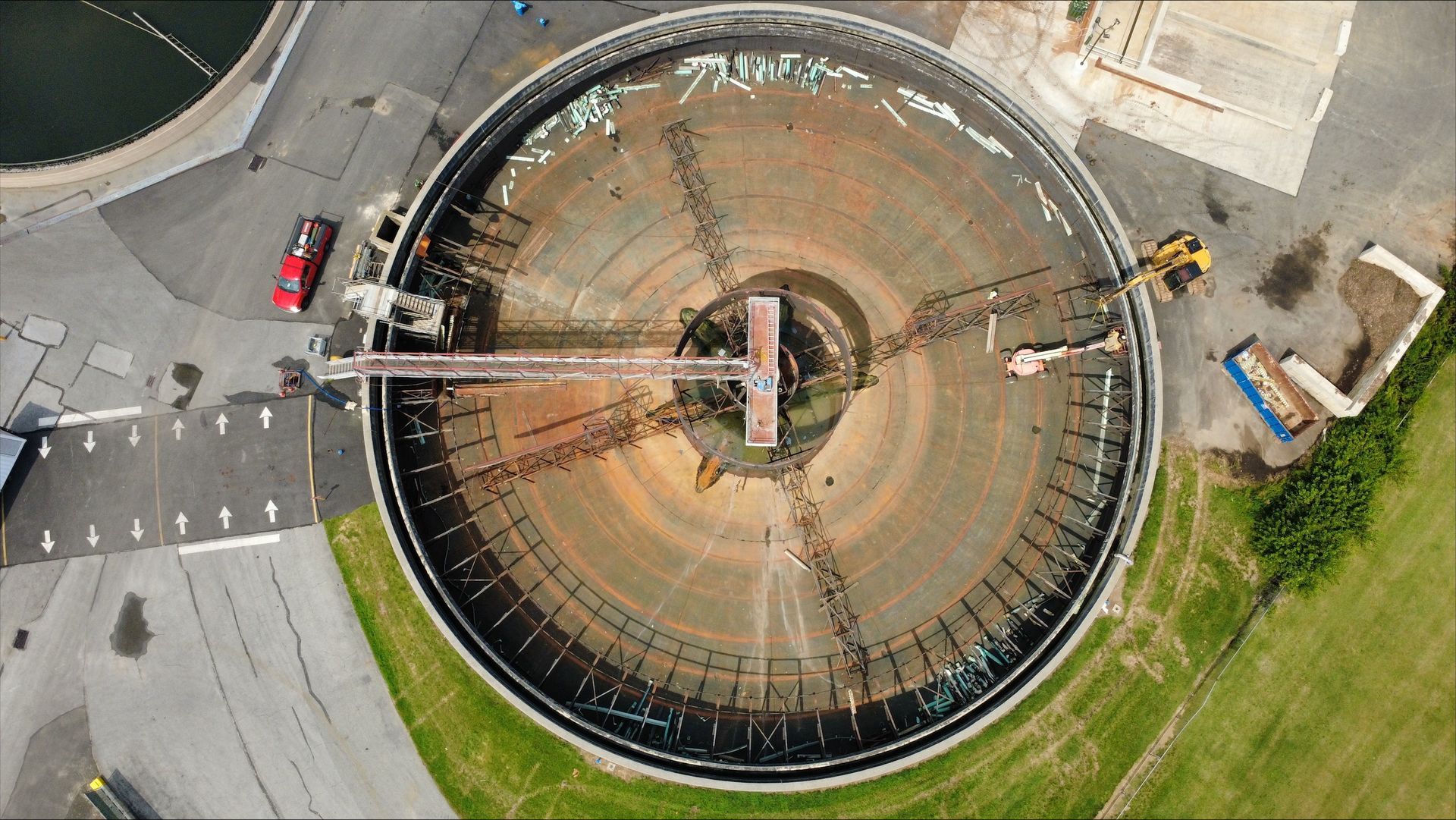

This situation is not unique to Allentown, Pennsylvania. While many manufacturing sites have been demolished, there are sites all over that have benefitted from adaptive reuse. One of Empire Services most recent projects, the repurposing of a Mark Trucks turned Allentown Metal Works plant, is an example of this repurposing trend.

The property, which closed for good in 2011, is unique in that the products manufactured there date back to the early 20th century, designating it a historical manufacturing site. The first owner and occupant of the property was Traylor Engineering Manufacturing Company. In 1902, Samuel Traylor founded Traylor Engineering to manufacture heavy-duty steel components used in the mining, construction and concrete industries. These products ,and even Mack Trucks, however, could not keep this piece of Americana alive.

Allentown Metal Works will not be another footnote in Allentown’s history, however. It’s getting a second chance at life through Marcon Properties, LLC. The Allentown developer is repurposing two buildings — totaling 160,000 square feet — on the property, creating a modern production facility for affiliated Eastern Exterior Wall Systems. Together with project partner Alvin H. Butz, Inc. , Empire Services has given the Allentown Metal Works site a new purpose for future generations.

A Familiar Site

Serving as contractors first to the Allentown Economic Development Corporation, Empire Services demolished building A’s top floor after a partial roof collapse. That work enabled Empire Services to gain first-hand knowledge of the site, so when they were contracted by Alvin H. Butz, Inc. to assist with repurposing the facility, they were ready to perform select demolition and excavation work. Additionally, Empire Services was able to help budget, plan, and value-engineer the project with Alvin H. Butz, Inc.

Taking It Down to Its Shell

Since the existing two buildings were stable, it made sense to repurpose them and reuse the materials. The project on the smaller building began in October 2022, with the bulk of the work having been completed in mid-January 2023.

Taking the 50,000-square-foot building down to its shell for renovations was necessary and included the removal of all windows, window infills, roofing, roof decking, metal panel walls, mechanicals, utilities, doors and partitions. Numerous roof purlins also required removal due to wood deterioration since the building’s closure over a decade ago, and mechanical equipment pits in the floor required equipment and material removal prior to backfilling with crushed concrete and clean stone to provide a level surface for the new concrete slab installation.

When it came to devising the demolition strategy, it all came down to sequencing.

“The strategy for this project was straightforward,” says Matt Bard, Empire Services estimator and project manager. “We had to develop a sequenced approach that would allow us to maximize our productivity while ensuring we still had a safe work site with minimal hazards.”

Empire Services needed to perform the select demolition as quickly and efficiently as possible, coordinating multiple crews working simultaneously and releasing completed sections of the building for other contractors. As a result, renovation and rehabilitation work on the building began earlier than expected, exceeding deadlines to have the new manufacturing site operational.

Top to Bottom, East to West

Once the strategy was in place, Empire Services began demolishing the interior of the building. The crew removed partitions and other finishes by removing mechanical features from the roof level down to the slab, moving east to west through the building. The work was done by hand using high-reach lifts ranging from 60 feet tall to 135 feet tall, along with torches and demolition saws.

Once the interior demolition was approximately 50% completed, additional crews demolished the roofing and wall sections. Windows and window infills were then removed following the same east-to-west approach, allowing multiple crews to work simultaneously and providing a safe drop zone for demolished roofing materials. Multiple articulating boom lifts ranging in height from 60 feet to 135 feet were used to access the different levels of roofing material, windows and mechanical features during this stage.

While completing the work, a Bobcat T190 compact track loader with a grapple bucket and a CAT 345 excavator loaded out and managed materials to keep the job site as clean and safe as possible. Upon completion of roof and wall demolition, Empire Services moved on to demolish select sections of concrete slab where required for future slab on grade, again working from east to west. The CAT 345 excavator with a hydraulic hammer was used to fracture and remove sections of raised and thickened slabs to provide the appropriate grade for the new concrete slab installation. Demolition of the slabs and completion of wall openings occurred in February 2023.

Project Challenges

The biggest challenge for Empire Services was working at great heights with a crew varying in size (six to 10 members). Working to surgically remove roofing panels and mechanical features from the basket of a personal lift safely and efficiently is never an easy task. Being tied off to the anchor point with a harness to ensure proper fall protection and proper body positioning while performing torch cutting, or other demolition work, is being used is always a challenging and time-consuming process. As work progressed and additional trades began to work on-site, coordination of deliveries, work areas and safety became critically important.

By developing a sequenced approach, Empire Services successfully completed the project in February 2023 — ahead of time and on budget. Approximately 20 tons of metal was recycled and 200 cubic yards of crushed concrete was able to be reused as part of the pit infill. With the demolition complete, the new manufacturing is set to soon bring back the excitement of Allentown’s manufacturing history and provide an economic boost to the city.