ST. JOSEPH’S HOSPITAL

Empire Services • January 31, 2009

JANUARY, 2009

Initially the bid date given was for an immediate start, but the award bid date was delayed for three months. Due to additional delays with permits and utilities the work did not start for an additional two months with the owner’s request that Empire’s work was to be completed and demobilized based on the original start date given.

The project required four buildings to remain standing, one being the original historic chapel located centrally among all of the demolition. Additionally, three exterior walls and a tower of the original stone structure had to remain independently intact to be incorporated into to the new proposed structure. This posed challenges that only a well organized team could conquer. One of the walls to remain was attached to the chapel and needed steel shoring with foundations in place for the wall to stand alone prior to separating and complete demolition of the remainder of the building. The tower and two other walls also required steel shoring. To erect the steel shoring, a JD80 Excavator needed to be crane lifted over the four story building and placed into the courtyard to excavate for the footers. Next, the concrete for the foundations had to be pumped into the interior of the courtyard. Then the steel shoring was partially assembled in the rear parking lot and lifted over the building and placed into the courtyard using a 300 ton hydraulic rock crane. The four buildings to remain were completely gutted of all interior finishes and mechanical systems to make way for the future Reading Citadel School. At the rear of the property, the prestressed 65,000 sq ft concrete parking garage was demolished and the resulting concrete from the garage, footers and walls were crushed and stockpiled on site to be used as future backfill material. All other demolition debris was hauled away using dumpsters and trailers to our sister company Berks Transfer to be recycled.

With all eyes on Empire as the Prime Contractor the project was accomplished with a team of over fifty laborers, five operating engineers, four foremen and a superintendent. At one point in the job there were over seventy workers on site between the subcontractors and Empire’s work force.

Empire utilized the services of various subcontractors to handle different aspects of the project such as electrical disconnects, capping, and relocation to keep temporary power in the buildings to remain. A sprinkler contractor was hired to separate systems and maintain fire protection operation as long as possible as per city codes. It was also necessary to rework standpipe systems so that the buildings to remain would have fire protection until such time as the new sprinklers were installed. Asbestos removal was a major portion of this project with thousands of feet of pipe insulation in the walls and underground tunnels as well as numerous areas of sprayed on fireproofing and transite panels. Thanks to the expertise of the asbestos contractor and their staff on site they were able to keep ahead of the demolition process and assist in adhering to the schedule. Empire hired both a structural steel and a foundation contractor to help in the underpinning and stabilization of existing sandstone walls of the original hospital structure to be salvaged and incorporated back into the new Reading Citadel School. Elk Environmental, a sister company of Empire Wrecking was contracted to explore, remediate, and secure any underground cisterns discovered during excavation.

In addition to all the subcontract work on this project, Empire had to complete over 200,000 sq ft of interior demolition which included the general hospital area, operating room and two large mechanical rooms. This had to be done without the use of motorized equipment due to the allowable floor loads of the buildings.

Prior to demolition, the first step was the remediation of all asbestos containing materials. This process along with the other subcontractors had to be coordinated to assure the schedule of twenty six weeks. By aggressive planning Empire Wrecking was able to complete the project two weeks ahead of schedule. This was possible because the Empire Wrecking team accelerated the pace by mobilizing additional equipment, with four excavators simultaneously excavating, hammering concrete, munching walls, and pulverizing footers . At the height of the project there were five sub contractors involved with the project and five different locations being worked on at the same time.

The demolition presented serious challenges. This was not a simple task as all of the buildings interconnected with other buildings – some of which were to stay and some which were to be taken down and still others that were to have just the exterior walls remain. This project utilized an experienced work force at these areas of separation. The only building that stood alone was a precast concrete parking garage. This part of the project was completed with the use of two 450 JD Ultra High excavators; a 300 Ultra High excavator, and numerous other equipment with grapples, hammers and processor attachments.

Empire completed the job including all change orders and the coordinating of additional asbestos, underground tank removals and over excavation of contaminated material and disposal on schedule. As always, Empire Wrecking Co. proved they were up to the Challenge

Since leaving the site the general package for renovating the remaining buildings and construction of the new school has been awarded to a General Contractor with Empire going back to the site once again for the final fit out as a subcontractor. This will consist of minor demolition, exterior wall openings, roof removals, new floor openings etc.

When planning a commercial renovation, expansion, or redevelopment, demolition is often the first critical step. At Empire Services, we work with general contractors, property managers, and developers who want clarity, transparency, and confidence before starting a demolition project. Below are the top five questions business owners ask about demolition, based on what we have heard from our clients. 1. How Much Will the Demolition Cost? Demolition costs vary depending on several factors, including: Size and type of the structure Building materials (concrete, steel, wood, etc.) Project location and site access Required permits and inspections Waste removal and recycling needs At Empire Services, we provide detailed, upfront estimates so there are no surprises. 2. How Long Will the Demolition Take? Timelines are critical for minimizing downtime and coordinating construction schedules. The duration depends on: Scope of work ( select interior vs. full demolition ) Contaminated material presence Site conditions and access Approval and inspection timelines Empire Services focuses on efficient planning to keep your project moving forward. 3. Do I Need Permits or Approvals for Demolition? Most demolition projects require permits and approvals, such as: Local demolition permits Zoning or planning approvals State required inspections and permits Empire Services handles the permitting process for you, saving time and reducing stress. 4. Can Demolition Be Done While My Business Is Still Operating? In many cases, select or phased demolition can allow business operations to continue. Empire Services designs demolition plans that minimize disruption while maintaining safety and compliance. 5. What Happens to the Debris and Waste Materials? Responsible waste handling is essential for cost control and sustainability. Debris may include concrete, metal, drywall, and wood. Empire Services prioritizes: Recycling whenever possible Proper disposal of all materials Environmentally responsible practices Bonus Question: What Safety Measures Are in Place During Demolition? Safety is our top priority. Empire Services follows OSHA standards and implements site-specific safety plans to protect workers, occupants, and the public. Our team is trained in the latest safety practices by Empire Group’s safety team . Start Your Demolition Project with Confidence At Empire Services, we deliver professional, efficient, and compliant demolition services designed around your business goals. From planning to site readiness, we manage every step of the process. 📞 Ready to get started? Fill out our contact form or give us a call at 610-372-6511.

Demolition doesn’t always mean tearing a building down to the ground. In fact, one of the most valuable and widely used approaches in today’s construction is select demolition, which includes interior, exterior and structural removals. At Empire Services, select exterior demolition is more than a service—it’s a craft built on experience, planning, and precision. What Exactly Is Select Exterior Demolition? Select exterior demolition involves the careful removal of specific exterior elements of a structure while keeping the rest of the building intact. This can include finishes or components such as brick, siding, windows, doors, or exterior wall sections. Because only targeted areas are removed, the term selective demolition is often referred to as select demolition. What makes it unique is its balance of craftsmanship and power. Depending on the scope and sensitivity of the project, the work may be performed: By hand , for detailed removals like windows, doors, or masonry With heavy equipment , when larger exterior sections need to be removed efficiently This approach is commonly used on both residential and commercial structures when materials have deteriorated due to age, rot, mold, or structural wear. The success of the job depends on choosing the right method for each area of the structure. It’s also a key step when preparing a building for expansion or a completely new façade. Real Projects. Real Results. Empire Services has proudly supported numerous exterior demolition projects across Pennsylvania, partnering with municipalities, institutions, and general contractors. We were honored to participate in the renovation of the Springfield Municipal Building in Delaware County, PA. Empire Services' team utilized a CAT 325 excavator to carefully dismantle the key sections, including the front façade. These sections were delicately hand separated from the remaining section, which preserved the integrity of the remaining structure. This work helped clear the way for modernization while preserving the building’s core structure.

What began as a simple timeline project quickly became a heartfelt journey through Empire Group’s living history. As dates, milestones, and old photographs came together, so did the stories—memories shared by former employees whose passion and dedication helped shape the company from the ground up. From dismantling a radio tower to demolishing a drive-in theater, their recollections painted a vivid portrait of a company built on grit, innovation, and camaraderie. Former employees Ray Geiger, Bob Nocera and Steve Beisswanger sat down with Ellen Ganime (Empire Group) to revisit decades of work, flipping through photo albums, and reliving the challenges and triumphs of past projects. As they talked, one thing was unmistakably clear: Empire Group’s story is not just about the jobs completed—it’s about the people whose shared experiences fueled the company’s growth. A Legacy Etched in Steel and Stone One of the many things that stood out during this project was the sheer scale and impact of Empire’s work over the decades. Vintage photos revealed the dramatic evolution of equipment, techniques, and industry standards. Many projects were so ambitious in scope that they gained national attention in magazines like Demolition and Constructioneer. Each snapshot served as a reminder of how far the company has come. More Than a Timeline—A Tribute What started as a historical record became something much more: a tribute to the people, progress, and perseverance that define Empire Group’s 70-year legacy. The timeline celebrates the company’s humble beginnings, its extraordinary achievements, and the enduring spirit that continues to drive it forward. A Big Thank You This project would not have come to life without the help from several people: Karen O’Neill Allen Dejewski Ryleigh Bohning Ellyn Harkin Tonia Carlile A special thank you to Todd and Harry O’Neill for sharing their extensive collection of articles and photos, and to Ray Geiger, Bob Nocera, and Steve Beisswanger for their great stories and photo albums. Be sure to stop by the training room to check out the timeline for yourself!

In Centre township, PA a pipe culvert needed to be replaced due to age-related deterioration. The Centre Township Municipality Authority contracted Empire Services to replace a pipe culvert located beneath a busy roadway. The original 36” diameter concrete-and-metal pipe had not only deteriorated but also was undersized for the volume of water it needed to handle. Empire’s approach combined replacement and restoration. Using a CAT 321 excavator, the team swiftly removed the old culvert and installed 60 linear feet of 48-inch HDPE pipe, providing greater durability and improved flow capacity. To complete the project, Empire restored the asphalt roadway with fresh new paving ensuring a smooth, stable surface. The project was completed ahead of schedule in just three days. The Top Three Causes of Culvert Failure Many municipalities prefer culverts over bridges because they serve a similar purpose but are faster and more cost-effective to install. However, like any drainage structures, culverts can deteriorate over time or fail. With the Centre Township culvert, age was the reason for replacement. It’s one of the top three reasons for culvert failure: Design: A culvert that isn’t engineered to handle increasing local traffic loads or water flow can crack or collapse. Changes in land use or development can also increase flow demands, overloading the structure. Maintenance: Debris buildup, erosion, or overgrowth can restrict water flow, reducing capacity and leading to blockages or washouts. Age and Wear: Constant exposure to water and sediment gradually wears down the interior, especially the bottom (the invert), causing structural failure. Culvert: an Efficient Solution When water needs to pass safely beneath a road embankment, a culvert is the best solution. Designed to channel water efficiently, culverts help prevent erosion and minimize the risk of flooding in surrounding areas. While simple in structure, these underground drainage systems play a vital role in maintaining safe and functional roadways. Culverts are installed beneath roads, railways, or trails. Among the various types—such as box , arch, and slab—pipe culverts are the most common. They can be made from materials like aluminum, galvanized steel, concrete, or high-density polyethylene (HDPE), depending on the project requirements. Empire Services has successfully completed numerous culvert replacements across Pennsylvania, from box structures to large-diameter pipe systems. Each project is handled with the same commitment to safety, efficiency, and quality workmanship that our clients have come to expect.

No one ever expects an emergency demolition situation—until it happens. Whether it’s a roof that suddenly caves in, walls that are crumbling under the weight of age, the aftermath of a fire or a severe weather event, the need for emergency demolition can arise without warning. That’s why having a reliable, experienced demolition company ready to respond quickly is essential. At Empire Services, we understand the critical importance of emergency demolition, not just for removing dangerous structures, but also for protecting the people and property around them. Here’s why emergency demolition is so vital and how we can keep your property and community safe during emergencies.

On behalf of the Empire Group, we would like to offer our sincere thanks to everyone who participated in our Annual Golf Classic on October 4 th at the beautiful Galen Hall Golf Club in Wernersville, PA. It’s hard to believe this marked the 30th year of the tournament! Although this was Empire Group's first time hosting the event at this historic venue, we have deep roots at Galen Hall — Empire Services demolished the original Galen Hall Hotel back in 1963 following a devastating fire. Since then, the golf club has remained a local landmark, known for its scenic views and welcoming atmosphere. Despite the cool early morning, 99 golfers were warmed up and ready for the 8 AM shot gun start leading to some fun but competitive golfing. After the final putt dropped, everyone gathered for a hearty lunch followed by the award ceremonies. Shout out to the winners of all categories and the raffle!

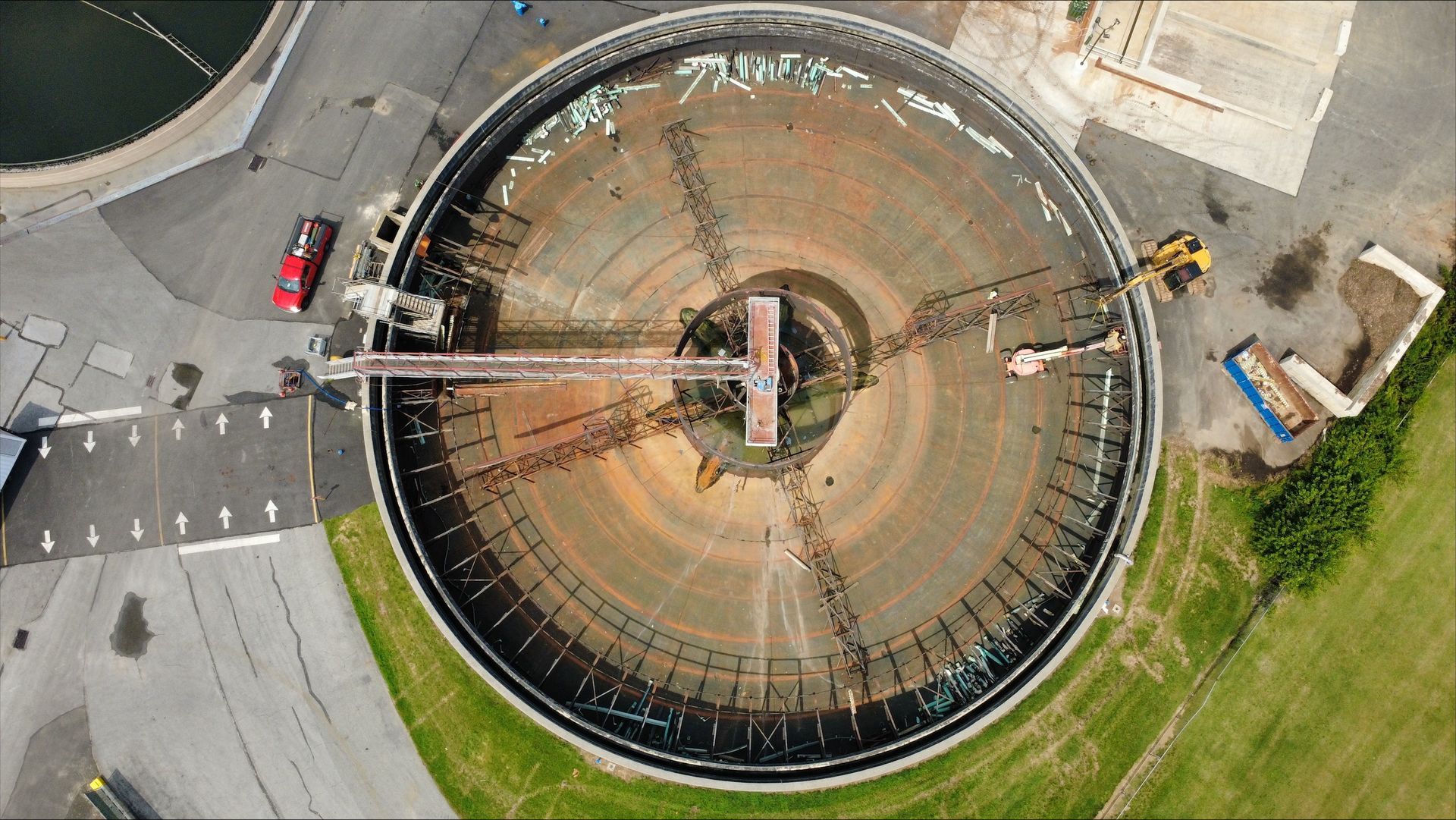

This summer, Empire Services proved that even scorching heat can’t slow us down. Our demolition and excavation teams worked tirelessly across the region, keeping projects on schedule and ensuring client satisfaction. From precise pipe installations to complex industrial dismantling, we brought the talent, equipment, and dedication needed to deliver safe and successful results. Below are some of our recent project highlights that showcase the range of services Empire Services provides.

School demolition and sitework projects come with a unique set of challenges: tight timelines, limited space, sensitive environments, and the need to avoid disruptions to student learning. Whether it’s a complete building demolition or utility work, every site requires careful planning, coordination, and execution. At Empire Services, we understand the pressure and precision required in educational demolition projects. That’s why schools across Pennsylvania—from elementary to college campuses—trust us to get the job done right.